Touching digital models:

How haptic technology enhances VR prototyping

Prototypes play a vital role in product development, serving various functions from refining designs to showcasing products. With the advent of VR technology, virtual prototyping offers immersive experiences for testing and shaping digital models. However, physical prototypes are still used for their tangible presence and tactile feedback.

So, how is it possible to combine virtual and physical prototyping when optimizing the product development process?

Product development: between physical and digital models

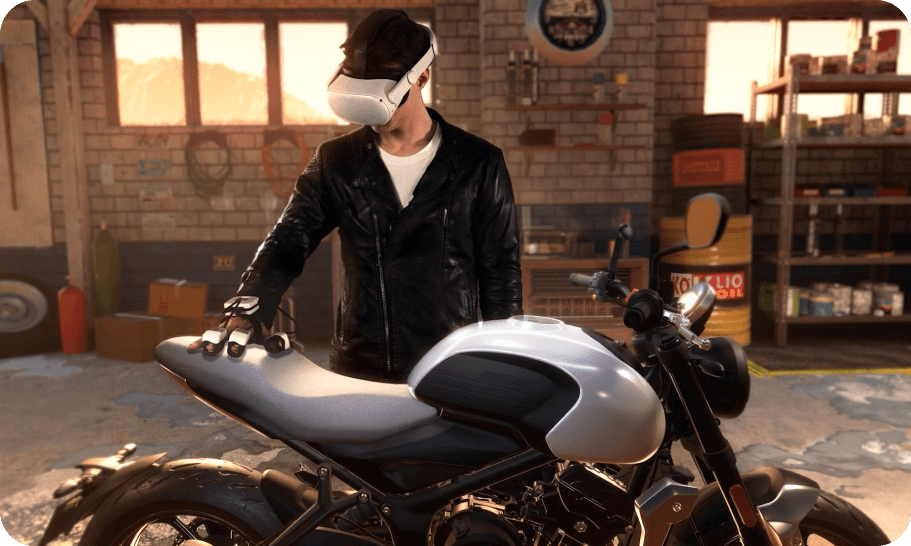

VR technology offers realistic representations and facilitates intuitive manipulation of digital models. To replicate features and performance prior to physical production, virtual prototyping uses digital twins of products. However, despite the advancements in virtual prototyping, the sense of touch remains an irreplaceable aspect, highlighting the need for a balanced approach in product development.

Touching digital models with haptic technology

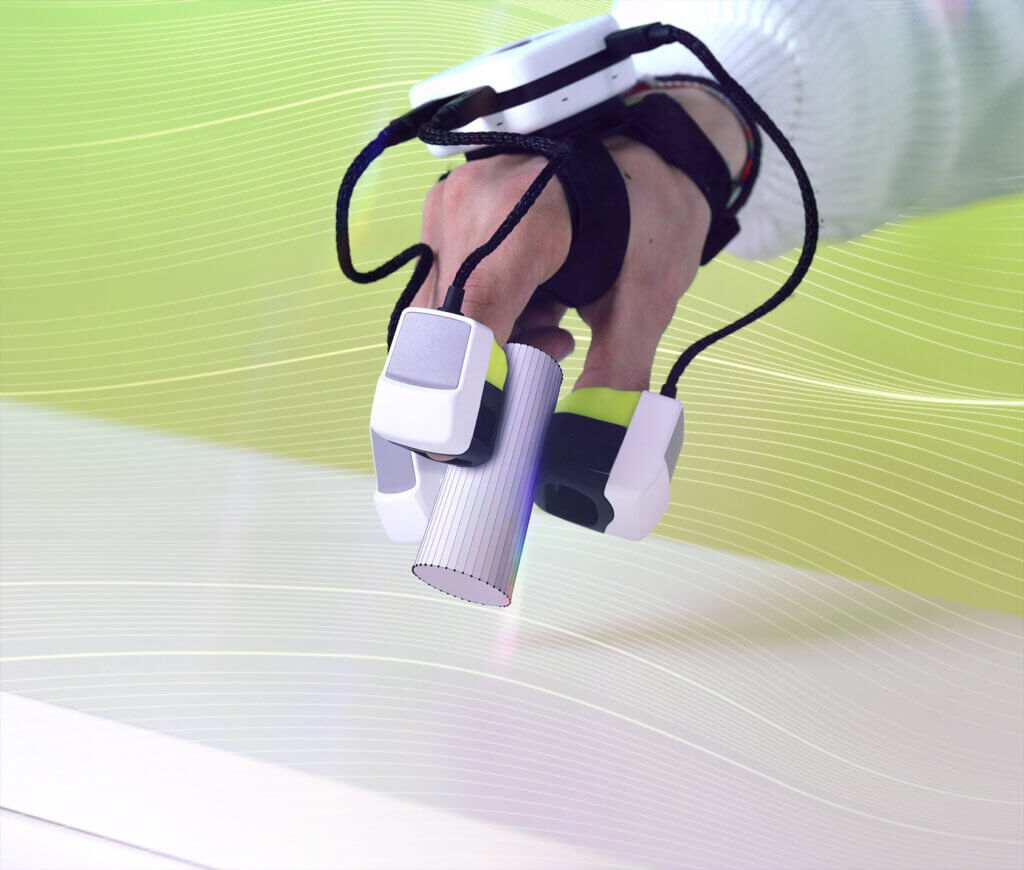

With the advent of haptic technology and the development of haptic gloves, designers can incorporate tactile feedback into their virtual environments, transforming the validation process and enhancing the efficacy of virtual prototyping.

By wearing haptic gloves, designers can interact with virtual prototypes in a more intuitive and realistic manner. Instead of relying solely on visual feedback, they can feel the shape, textures, and spatial relationships of the objects they are designing. They can test VR models directly, thus avoiding those situations where CAD has changed and the latest prototypes are already outpaced.

Boosting collaboration with haptic gloves

Haptic feedback is highly valuable in industries such as automotive and aerospace, where designers and engineers are already used to work with virtual and immersive models and can now build better mind representations of their designs.

Haptic gloves also facilitate collaborative design sessions by enabling multiple team members to interact with the same virtual prototype simultaneously. This fosters better communication and idea exchange among team members, leading to more innovative solutions.

TouchDIVER haptic glove for VR Prototyping

TouchDIVER provides the most extensive array of tactile perceptions, making it suitable for design validation processes and virtual prototyping:

- Variations in pressure and force that facilitate the feeling of shape and stiffness of digital objects.

- Thermal sensations – ranging from cold to hot – that enable users to feel VR-simulated dangerous conditions

- Designers can meet their creative needs feeling their meshes with our built-in extensive materials library – such as metals, ceramics, fabrics, and natural elements.