5 Reasons to integrate haptics in your VR Industrial Training

5-min reading

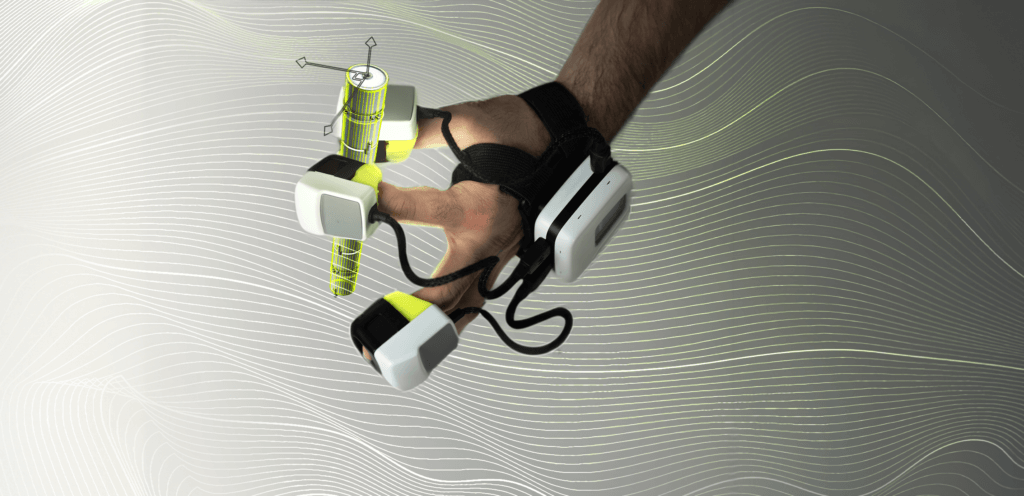

In a nutshell: VR training’s power lies in replicating real job experiences, and touch, through haptic gloves like TouchDIVER, enhances this simulation. This technology elevates the realism of tasks for trainees in safety and machinery operations, all within safe, risk-free environments.

In the early 2000s, aerospace and automotive industries led the way in adopting VR technology for training, enabling employees to refine their skills in virtual environments, minimizing the reliance on physical prototypes. As VR technology advanced, its use expanded across various sectors, including construction, manufacturing, energy, and healthcare.

But the true potential of VR training lies in its ability to simulate a trainee’s actual job. In this context, touch plays a fundamental role in replicating natural interactions in industrial VR environments, enhancing the effectiveness of the training.

We have sum up some advantages in the adoption of haptics into virtual industrial training.

How VR and haptic feedback revolutionize training process

According to a 2020 study conducted by PwC, individuals undergoing VR training reported feeling 3.75 times more engaged and 1.5 times more concentrated on the training material, compared to traditional classroom-based methods. Consequently, this immersive approach results in a steeper learning curve, as it enhances learners’ ability to maintain their focus.

Furthermore, users have traditionally interacted using controllers. While HMD controllers remain appropriate for certain applications where hand presence and fine motor skills play a minor role, there is a growing recognition that haptic feedback in VR enhances real-world actions and substantially improves training effectiveness.

5 reasons to adopt haptics in VR industrial training

The true potential of VR training lies in its ability to simulate a trainee’s actual job and touch is bringing this simulation a step forward. By means of haptic feedback, trainees dealing with safety or machinery operations can enter a superior level of realism. Tasks, movements, procedures become lifelike, while being carried out in risk-free environments.We sum up 5 reasons to integrate haptics in VR industrial training:

1. Natural hand interaction: Haptic gloves enable natural hand movements in virtual training, replicating real-world actions, which is vital for precise tasks like assembling intricate components. They provide a tactile experience, allowing trainees to feel and interact with virtual objects, textures, and surfaces, enhancing immersion and realism in training.

2. Motor skills development: For industrial tasks that involve fine motor skills and dexterity, haptic gloves are ideal. They enable trainees to practice skills like gripping, manipulating objects, with a high degree of accuracy. This enhances trainee understanding of heavy and light industrial machinery, resulting in quicker learning and better retention.

4. Safety training: Haptic gloves offer a safer training option for high-risk industrial scenarios like hazardous materials handling and heavy machinery operation. They allow trainees to practice dangerous tasks in a virtual environment with haptic feedback, enhancing situational awareness and reducing real-world accident risks.

5. Cost effectiveness: Incorporating haptics into VR training programs saves costs and time by eliminating the need for expensive physical setups. Haptic gloves enable trainees to practice in a virtual environment, reducing the reliance on physical equipment and minimizing production downtime for training purposes.

Lifelike interaction with TouchDIVER haptic glove

TouchDIVER haptic glove is the only device in the market that delivers full haptic stimuli, allowing users to experience force feedback, textures rendering and even thermal cues. The glove incorporates accurate sensors that track hand and finger movements, enabling users to interact naturally with virtual objects and environments.

TouchDIVER upgrades your VR training by:

- Facilitating trainees in practicing and improving their dexterity, coordination, and precision

- Reducing errors when operating real machinery

- Accelerating the understanding of industrial machinery, leading to quicker learning and improved retention